Earthmoving companies

Types of excavator machine

Earth-moving machines are at the heart of any construction project. And the Indian earthmoving equipment industry is experiencing high demand once again while the infrastructure sector gradually recovers from its pandemic-induced slump. The Indian construction equipment market is projected to cross the $4.7 billion mark by 2025 based on the increasing smart city projects, foreign investments, and the booming housing industry growth.

Earth-moving activities require multipurpose heavy machinery to carry out the tasks of digging, loading- unloading, moving large quantities of earth, grading soil, breaking rock, landscaping, clearing out debris, demolition work, and much more. The following are 5 types of construction equipment most commonly seen on construction sites:

1. Excavators

An excavator is one of the most valuable pieces of heavy construction equipment on-site. It is used for digging trenches, holes, and foundations. It consists of an operator cabin, undercarriage, boom, stick, and bucket. The operator cabin, popularly known as the house, sits on top of the undercarriage with tracks or wheels. A hydraulic excavator relies on the power of hydraulic fluid, hydraulic cylinders, and a hydraulic motor to accomplish its tasks. Several types of excavators are available, each with different features that assist in the task at hand on the construction site. For example, tracked excavators are suitable for digging, material handling, and demolition. In contrast, mini-excavators are small and lightweight, making them ideal for trenching and utility work.

2. Backhoe loader

The backhoe loader is heavy construction machinery combined with three types of construction equipment. It consists of a tractor, a loader, and a backhoe. Their mobility makes them suitable for earth-moving activities in urban areas. They are used for excavation works, digging trenches, placing pipes, filling trenches, lifting materials, etc. Backhoe loaders are one of the most popular earthmoving machinery in India.

3. Wheel Loader

Wheel loaders, also known as front loaders, are versatile heavy-duty machinery with a high load carrying capacity. The primary purpose of a wheel loader on-site is to dig, carry, haul, and transport material on-site. A wheel loader consists of an arm with a hauling bucket or scoop that efficiently carries large-scale materials. Besides construction sites, they can also be used for agricultural and landscaping purposes. Loaders come in various sizes, making them ideal for projects of any size.

4. Motor grader

The motor grader is heavy-duty machinery with a multipurpose long blade. Motor graders are primarily used in civil construction, roadworks, and mining sites to create smooth roads. Graders have special attachments that make them multipurpose, like a ripper, scarifier, blade, or compactor.

5. Skid-steer loader

Skid-steer loaders are tyre-mounted, small-sized construction machinery commonly used on construction sites with space restrictions. The machine has lift arms designed to latch onto several attachments. The wheels of the skid-steer loader are locked in synchronisation on each side. This mechanism allows the left-side drive wheels to be driven independently of the right-side wheels. The skid-steer loader has a tough and rigid frame. Robust wheel bearings are required to prevent torsional force caused due to motion from damaging this machine.

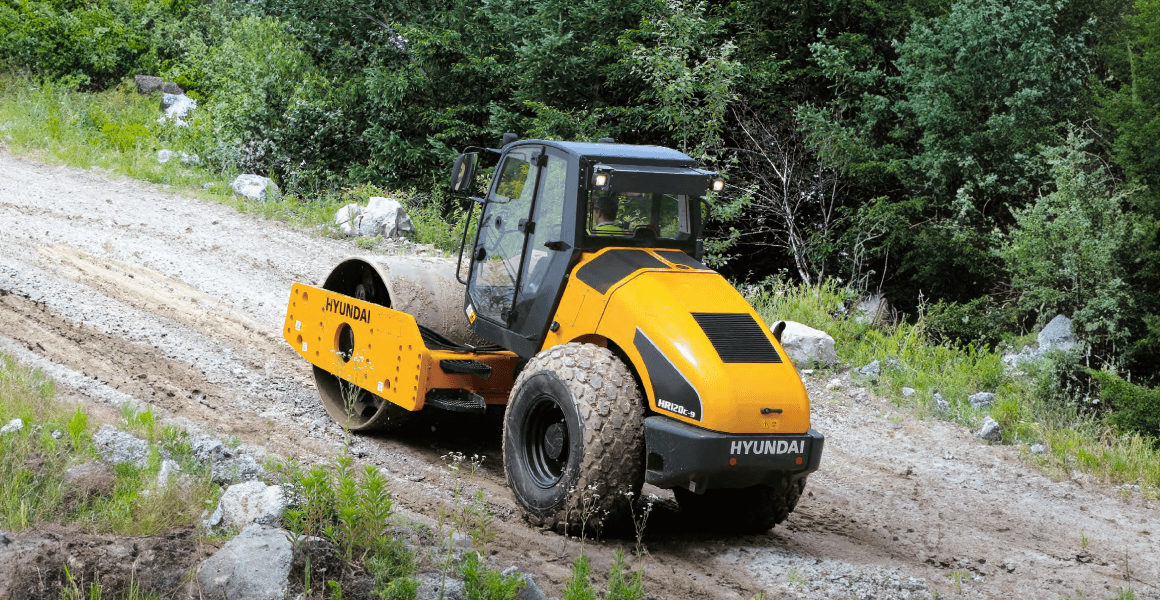

6. Compact Roller

A compact roller is a versatile and efficient construction machine used in various applications within the construction industry. It is designed to compact and smooth different types of surfaces, such as soil, asphalt, and gravel. With its compact size and manoeuvrability, the compact roller can access tight spaces and work on smaller construction sites where larger machines may not be suitable. Equipped with heavy drums or vibrating plates, the roller applies pressure to the surface, compressing and levelling it to achieve optimal compaction.

7. Articulated Dump Truck

An articulated dump truck, or ADT or articulated hauler, is a powerful and specialised vehicle widely used in the construction and mining industries. It is designed with a unique articulating joint that allows the truck to navigate through challenging terrains and uneven surfaces with exceptional manoeuvrability. The ADT consists of a front cabin where the driver sits and a rear dump bed for material handling. The articulation joint between these sections provides flexibility and stability, enabling the truck to traverse rough terrain while maintaining traction on all wheels.

Final thoughts

Construction sites vary in terrain types and size. Hence, choosing the perfect construction equipment for a site contributes to the economy, quality, safety, and timely completion of a project. Thorough research is essential before purchasing or renting any piece of construction equipment to keep operational costs in check.