Electric vs. Non-Electric Skid Steer: A Look at the Bobcat S7X and T7X

As the construction industry is one of the biggest emission contributors, equipment manufacturers are all trying to figure out ways how they can reduce their carbon footprint. With that, the natural progression over the last few years has been through electrification. Starting with power tools, electric heavy equipment has become next in line.

Already with electric equipment like scissor lifts, mini excavators, forklifts, boom lifts, and wheel loaders, electric skid steers and compact track loaders seem to be next. Bobcat was the first manufacturer to announce their two electric machines that are expected to hit the market shortly, the S7X and T7X.

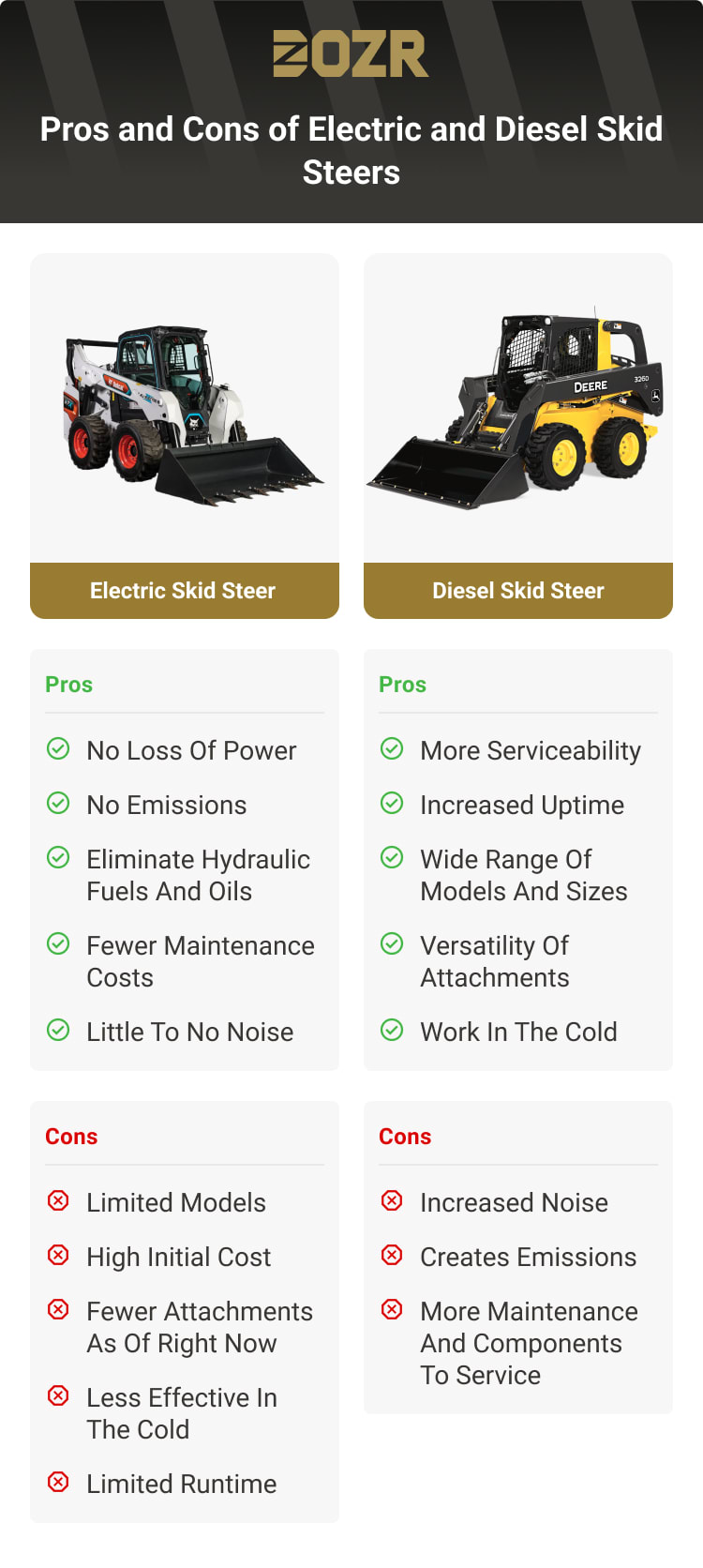

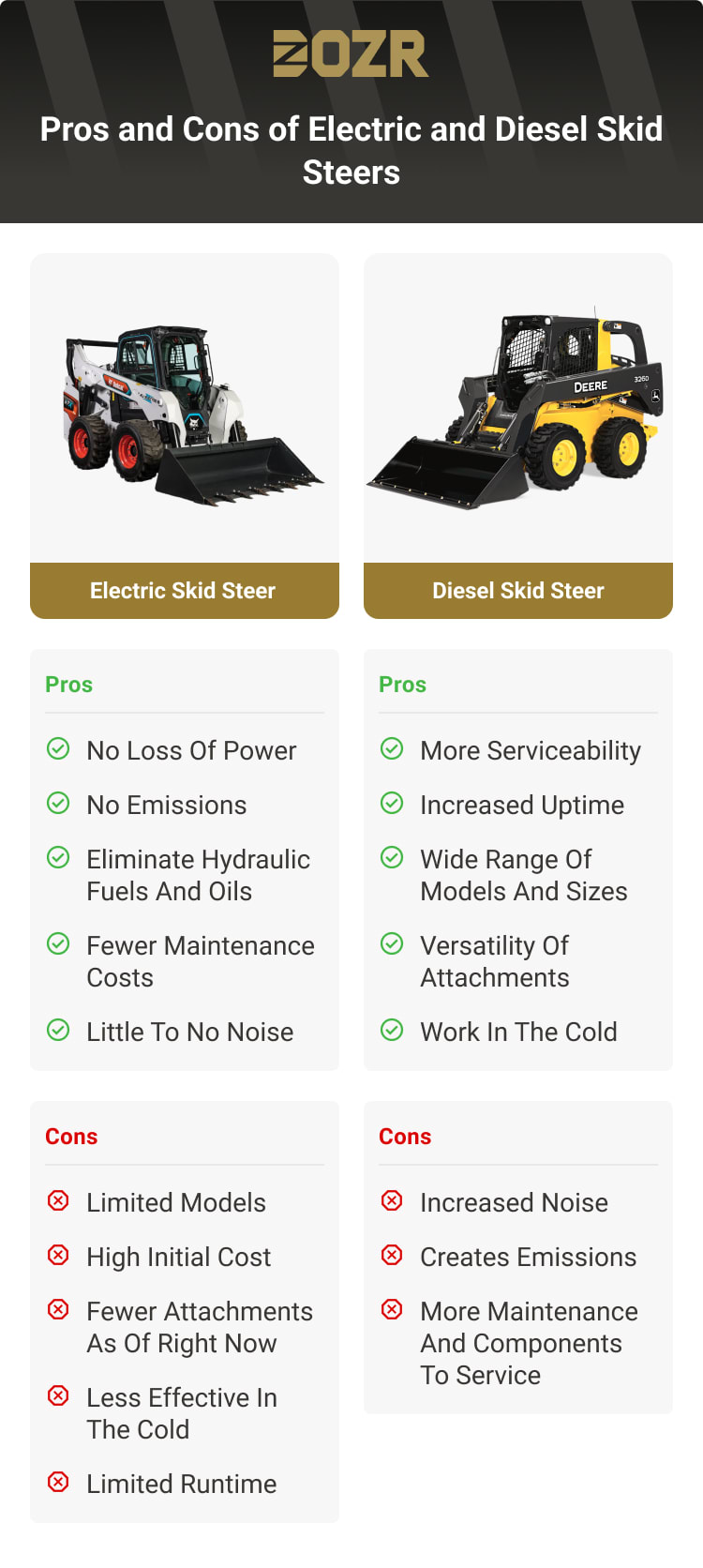

The question is, how will these electric models compare to the non-electric skid steers? That’s what we’re going to dive into here, talking about environmental impact, operating efficiency, noise reduction, power, performance, as well as some attachments.

Electric Skid Steer: The Dawn of a New Era

The benefits of using an electric skid steer rather than the traditional diesel-powered models include environmental impact, operating costs, and noise reduction. Each of these benefits is useful in specific use cases which we will talk about below.

However, it’s important to remember that Bobcat is still working and innovating on their electric track loaders. While there have been some video demonstrations and product teasers, there may be some slight changes and adaptations.

Environmental Impact

One of the primary benefits of electric skid steers and track loaders is the environmental impact. With many manufacturers and large general contractors feeling the pressure to decrease their emissions, electric equipment is quickly becoming more desired.

Electric models fully eliminate the need for using fuel and because they have no hydraulic systems, there are no extra fuels and oils to buy either. This is incredibly important for indoor jobs that require equipment to be electric or to stop production every once in a while to let out the carbon buildup.

Operating Efficiency and Costs

An aspect that has been surprising in the development of electric skid steers is that the specs of the machines are going to be closely related to the diesel-powered equivalent. For example, the specs of the Bobcat T7X are fairly close to the specs of the T76. This will give them the same efficiency in terms of power and performance. There is also no noticeable power lag when powering the drive, lift, and tilt all at the same time.

On top of this, electric models will be cheaper. While upfront costs may be higher, the total cost of ownership will be driven down by fewer fuel costs, fewer repair costs (due to the equipment having 50% fewer components), and maintenance on hydraulic hoses and fittings.

One downside to operating efficiency at this time is the lack of attachments. While non-hydraulic attachments will work on both types of machines, electric attachments overall will have to catch up with those on diesel machines. This may be a huge determinant in which type of machine contractors and companies will invest in, at least in the short term.

Another current challenge could be the runtime. Depending on the job, the machine can last anywhere between 4 hours and 8 hours and requires 10 hours to charge. Overall, whether or not this becomes an issue is dependent on the utilization of the machine on each job.

Noise Reduction

The last thing to mention about the electric skid steers is their ability to move with little to no noise. This is crucial when operating in some residential or noise-sensitive areas. While operating on rocks and dirt will still cause some noise, the actual machine itself really only will make noise when lifting.

Non-Electric (Diesel) Skid Steer: The Current Industry Standard

Everyone knows that non-electric skid steers and compact track loaders are some of the most popular machines on a construction site. Able to fit in tight spaces, they can support almost any type of project, they’re versatile machines that can accomplish many tasks because of their power, range of models, and attachments. This has made them, for very good reasons, the current industry norm.

Power and Performance

The main power and performance difference between the two types of engines is the wide range of options that diesel skid steers have. As can be seen in our skid steer spec guide, there are many models ranging from a 760 lb ROC to 4,200 lbs. Horsepower also ranges from 24 to 100.

This wide variety makes some suitable for light-duty work all the way to heavy-duty applications. They also have several different brands and manufacturers. Meanwhile, electric skid steers and compact track loaders only will exist in one size at first and only Bobcat is on track to deliver one to the market.

Having several brands and models available with diesel engines is a more attractive version for many contractors, especially when specs will depend on the job.

Reliability and Durability

As mentioned above, there is still a lot of unknown about skid steers. Not only in terms of their runtime but also in regard to getting new parts. As electric models are new, parts will be more expensive and not as readily available. With diesel engines being the norm, there is more support and a better network of manufacturers who are able to deliver those parts, as well as more experienced mechanics.

Diesel engines also have the ability to work in harsher environments. Lithium-ion batteries do not react as well to cold or corrosive environments which are sometimes required of heavy equipment. While battery warmers may be a long-term solution, knowing that diesel engines can run just off some fuel gives more peace of mind to the operator.

Versatility and Attachments

Lastly, and this may be the biggest benefit of diesel-powered skid steers right now, is the versatility of attachments. These allow skid steers to contribute to any project and as mentioned before, with non-hydraulic systems comes the need for non-hydraulic attachments, or non-flow attachments, for which there is not much demand right now. This means that attachments on electric models will be delayed and may slow down the adoption of electric equipment.

Attachments are already expensive investments and most contractors won’t find a purpose in having two types of the same equipment and the additional attachments. It just won’t make good financial sense. It will make more sense to fully commit to electric or diesel.

That being said, as more electric machines are brought into the norm, more manufacturers will start to produce attachments for them. However, it will be a laggard approach and we are probably still years away from that happening on a larger scale.

The Future of Skid Steers: Electric Models on the Horizon

The future of skid steers is exciting and in good hands. While currently, the market has a majority of non-electric skid steers, we envision electric skid steers will be more impactful in the rental market in the immediate future. And Bobcat’s partnership to deliver their first round of electric skid steers to Sunbelt Rentals proves that.

Because investing directly into electric skid steers will be expensive from a contractor’s perspective, especially when the primary use case for them is specific to indoor environments, this makes sense. It will be interesting to see how the market adapts to these machines and just how quickly they get introduced across the industry.

Each type of machine will have its pros and cons, just like any other piece of heavy machinery. However, for right now, non-electric skid steers will continue to dominate the market until proven otherwise. If you’re looking to rent skid steers or compact track loaders, search the DOZR Marketplace today.

MktoForms2.loadForm(“//378-ZTK-807.mktoweb.com”, “378-ZTK-807”, 1093);