Deciding on which lift truck you need can be confusing, especially since many share similarities when it comes to lifting, loading, and reaching.

While both reach trucks and forklifts are excellent for material handling applications, each has their pros and cons. Reach trucks come in handy for reaching great heights, while counterbalance forklifts can carry heavy loads.

This post compares the features of reach trucks and forklifts so you can make the right decision for your warehouse and construction needs.

Explore All Forklifts

What Is a Reach Truck?

A reach truck, or reach forklift, is an electric, Class II narrow aisle truck ideal for placing and retrieving pallets at great heights. Its forks are attached to the side of the machine and can extend horizontally to reach for a pallet on a shelving unit or rack. Reach trucks can be operated in extremely narrow aisles. However, one limiting factor is that they are typically meant only for indoor use.

What Is a Counterbalance Forklift?

Counterbalance forklifts have forks attached to the front of the truck and a counterweight at the back to balance the load. The counterweight allows them to handle heavier loads than reach trucks, though they can’t reach as high or navigate in tight spaces. These machines can be battery-powered or diesel-powered, so they’re suited for indoor and outdoor use. There are also many forklift attachments available for specialized uses.

Reach Truck vs. Forklift

While reach trucks and forklifts share similar features, they are two distinctly different powered industrial trucks. Here’s a breakdown of their primary differences.

| Reach Truck | Counterbalance Forklift | |

| Maneuverability | Can maneuver in tight spaces | Struggles to fit or turn in narrow aisles |

| Load Capacity | Maximum capacity is 4,500 lb | Can lift upwards of 158,000 lb |

| Size | Typically smaller | Typically larger |

| Driver Position | Side view, with side and back visibility to easily lift and lower loads | Front view, with more limited visibility |

| Power Source | Battery | Gas, diesel, or battery |

| Indoor/Outdoor | Primarily indoor options with limited outdoor options | Indoor and outdoor options |

| Uses | Reaching, lifting and moving warehouse pallets in high and narrow spaces | Loading and unloading materials indoors and outdoors |

| Versatility Level | Limited | High |

| Lift Height | Up to 46 feet | Up to 26 feet |

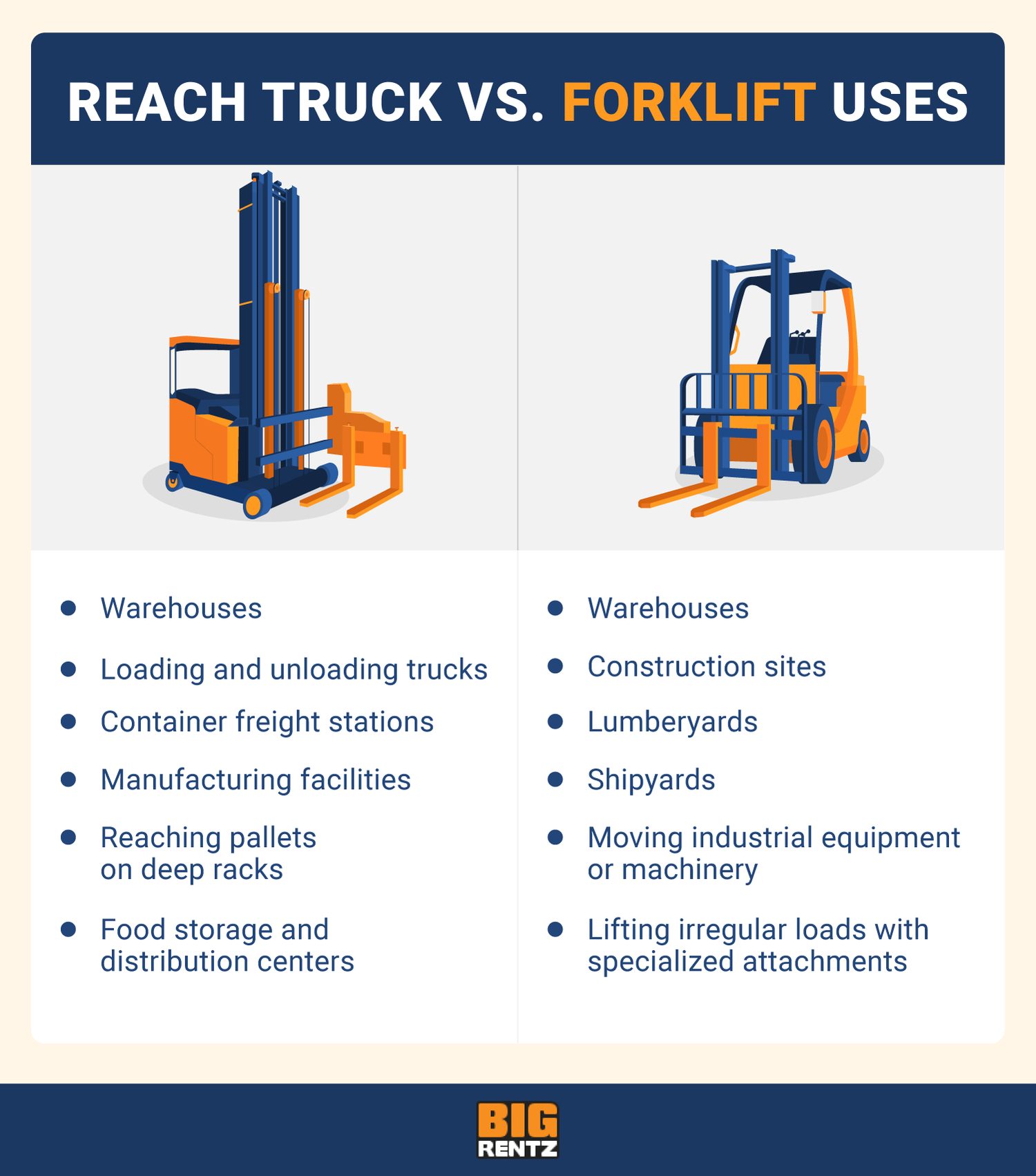

Reach Truck Uses

Reach trucks are generally used for loading and unloading high or deep pallets and navigating narrow aisles. These are some of the instances in which reach trucks may benefit you:

- Warehouses: Reach trucks can be used in warehouses to place and remove pallets in high-rack storage units, restock shelves with goods, and move loads from one area to another.

- Food storage and distribution centers: Reach trucks transport perishable or sensitive goods with efficiency and care due to their sharp control and delicate handling. In addition, their maneuverability makes them a great fit for material handling in temperature-controlled spaces.

- Container freight stations: Reach trucks at container freight stations allow these operations to maximize storage space by storing pallets in ways that an ordinary forklift would have trouble reaching.

- Manufacturing facilities: In manufacturing facilities, they can be assigned to move finished products to storage and raw materials to production centers.

- Loading and unloading trucks: The maneuverability of reach trucks allows them to handle cramped spaces in loading docks. Meanwhile, their reach enables them to stack items in a way that maximizes the storage space of transport trucks.

Forklift Uses

If you’re wondering what forklifts are used for other than simply moving items to and from warehouses’ shelves, take a look at these examples to get a detailed grasp of their performance range:

- Warehouses: Counterbalance forklift trucks are primarily used in warehouses for loading and unloading materials and other goods.

- Construction sites: Forklifts are commonly used at construction sites to unload pallets of bricks, blocks, steel joints, and other heavy materials. These materials are carried off across uneven surfaces to reach the unloading site.

- Lumberyards: Apart from the basic loading and unloading operation, forklifts are used at the lumberyard to organize and stack lumber efficiently.

- Shipyards: Forklifts are ideal for stacking and unloading wood and steel shipments.

- Moving industrial equipment or machinery: Heavy-duty machines with adjustable forks or specialized attachments can load and move large, bulky machinery.

- Lifting irregular loads with specialized attachments: Attachments like side shifters, rotators, fork positioners, and clamps aid with irregular loads.

Other Types of Forklifts to Consider

With so many forklift types on the market, it can be hard for you to make the best choice. This list explores the most popular forklifts and their applications to help you make an informed decision:

- Walkie stacker: Walkie stackers are electric walk-behind machines with limited lift and load capacity. They can be used indoors for moving loads short distances.

- Order picker: Order pickers are used to raise the operator, allowing them to pick or return items to an elevated shelf.

- Heavy-duty forklift: As the name suggests, heavy-duty forklifts can lift tens of thousands of pounds. Such immense lifting is typically used for specialized jobs.

- Rough-terrain forklift: Rough-terrain forklifts are used for outdoor tasks. These trucks are designed with strong pneumatic tires enabling them to transport materials securely even on rough terrain.

- Side loader: Side loaders are typically selected for large and bulky materials. Their sideways motion allows them to easily slide alongside racks to load and unload items.

- Telehandler: The telehandler looks like the hybrid version of a crane and forklift and comes with an extendable moving mast, allowing its twin forks to reach odd angles and tight spaces conveniently.

When to Choose a Reach Truck

A reach truck may be preferable to a forklift in the following instances:

- Indoor warehouse crates need moving

- You’re operating indoors in a narrow area

- You need more maneuverability in small spaces

- You need higher lifting capabilities

When to Choose a Forklift

You should consider renting a forklift you have:

- A larger space to move around in

- Indoor and/or outdoor lifting needs

- A heavier load

Choose the Right Lift for Your Next Project

While reach trucks are convenient for reaching great heights and operating in enclosed, narrow spaces, forklifts make heavy lifting easy and allow smooth transportation even on uneven terrain.

Regardless of whether you’re choosing a reach truck or forklift, it’s integral that you undergo the necessary training and evaluation required to operate the powered industrial trucks. When you’re ready to rent either piece of heavy equipment, BigRentz has you covered with its wide range of options to meet your job’s needs.

Explore All Forklifts