If you’re planning a construction job that requires you to work high above the ground, you may have started to consider an aerial platform. With several to choose from, including scissor lifts and cherry pickers, it can be difficult to know what will work best for you. However, if you need to go really high and don’t have a lot of room to work with, then you may want to consider a boom lift.

Most types of boom lifts generally offer smaller aerial work platforms (or buckets) than scissor lifts, and are often only large enough for a single worker. They can be found in various sizes, ranging from 30 feet all the way up to 185 feet. There are electric boom lifts and diesel boom lifts. One of the biggest distinctions among these versatile machines, though, is the two distinct designs that are available: articulating boom vs. telescopic boom lifts.

Let’s look more closely to explore what sets them apart from each other, and which type of lift might be the best choice for different kinds of jobs.

Explore All Boom Lifts

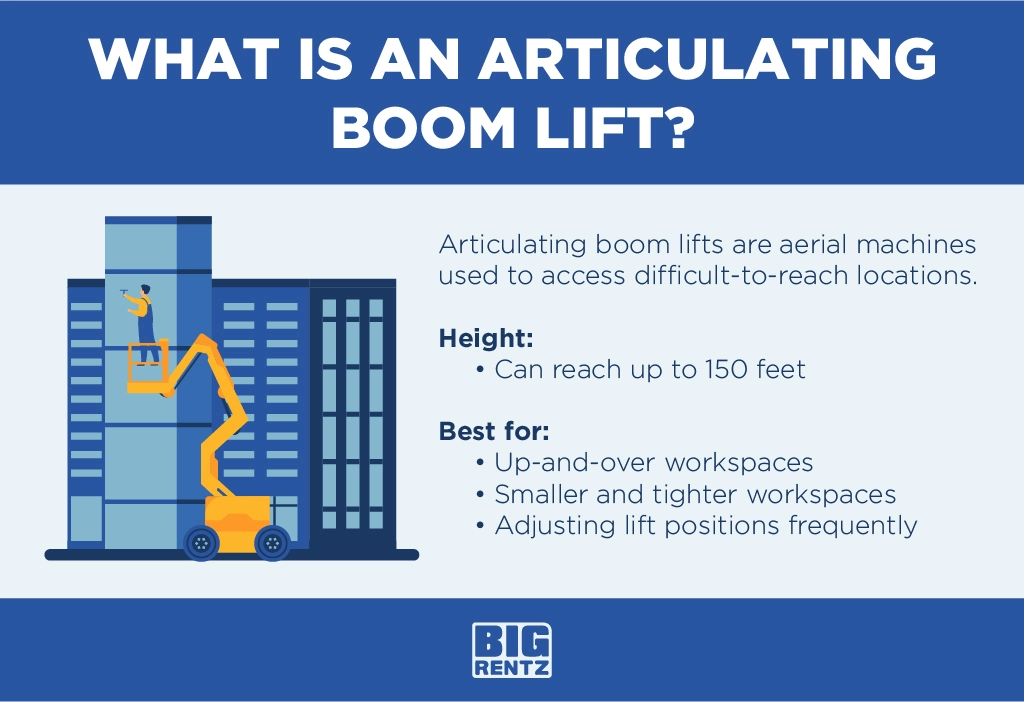

What Is an Articulating Boom Lift?

Articulating boom lifts are aerial machines used to access difficult-to-reach locations. Most models come with a 360-degree base turntable, so they can swivel in any direction. However, the most notable feature that sets them apart is their joint arm and segmented boom sections. In fact, it comes with multiple joints (typically two or three) like a finger, which explains why they’re sometimes called “knuckle booms.”

These lifts offer a level of dexterity and versatility that other lifts can’t provide, with an impressive reach/working height of up to 150 feet up, over, and around. The knuckles on their articulating arm, or jib, can bend around corners, past obstacles, and over walls to give a worker access to areas that would otherwise be impossible to reach.

Articulating boom lifts can also be used indoors because their arms can bend and contract to squeeze into tight spaces. They’re available in quiet engines with no emissions that run on electric power and can be used indoors, or may be equipped with diesel engines for outdoor use.

Best For:

- Hard-to-reach areas on your worksite

- Jobs that require you to adjust your lift position frequently

- Working in a smaller or tighter space

- Up-and-over workspaces

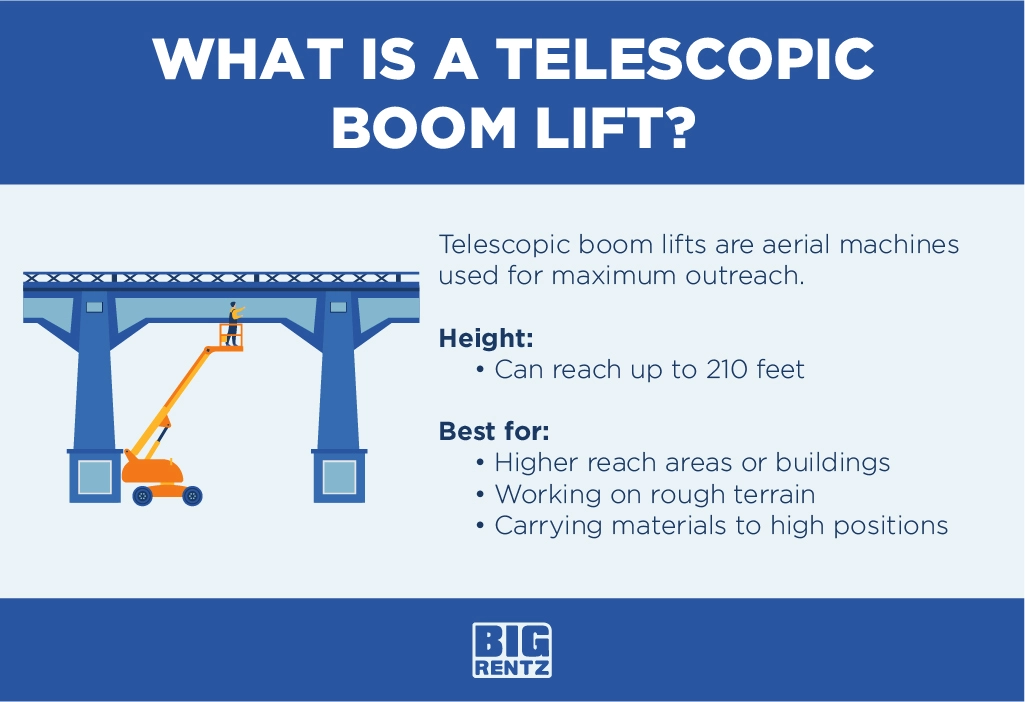

What Is a Telescopic Boom Lift?

Telescopic boom lifts, also known as straight boom lifts offer an extended outreach like the articulating lift, and in some cases can stretch even farther—up to 210 feet. They lack the joints present on an articulating arm, though, so they’re less versatile in tight areas. They can extend straight up or straight out at an angle, but they can’t bend, instead of expanding and contracting like a telescope.

Rugged tires can allow them to operate well in rough terrain, and because they run on diesel fuel, they tend to be used outdoors. (Note, however, that their straight-arm reach could be limited indoors.) Some models have four-wheel drive as well.

Best For:

- Reaching far during specific tasks (up to 210 feet)

- Working on rough terrain

- Lifting materials to high positions using elevated work platforms

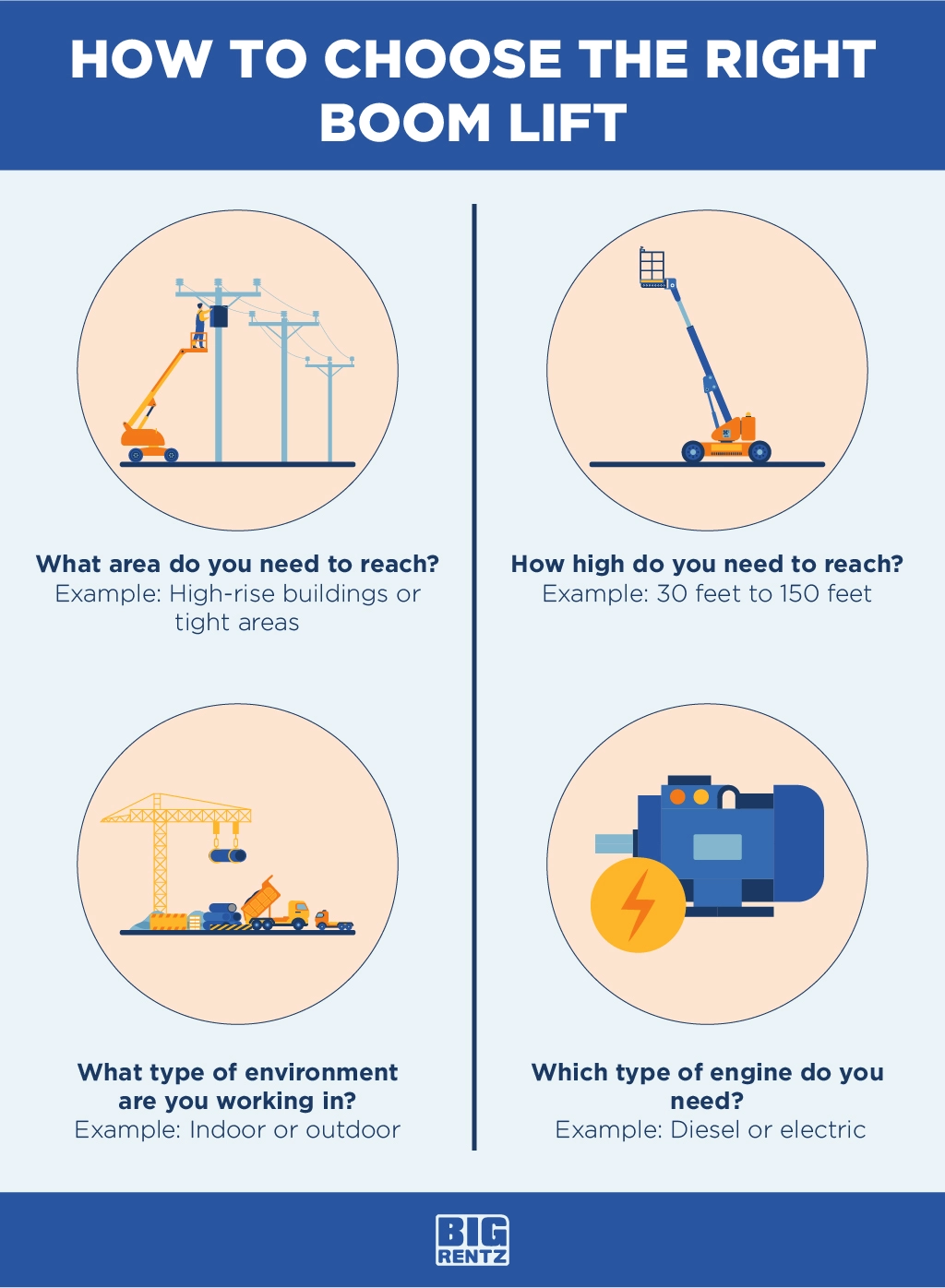

How to Choose the Right Boom Lift

When deciding between these two kinds of aerial lifts, you’ll want to know the nature of the job and the layout of your work areas. How high or far out do you need to go? How many obstacles (walls, trees, power lines) will you be dealing with? Will you be operating indoors or outdoors? Will you be working over rugged terrain?

In comparing these articulating and telescopic lifts, here are some specific factors to keep in mind.

Agility vs. Versatility

The most recognizable difference between these two types of lift equipment is the articulating boom’s shape. They have multiple pivot points (allowing up-and-over access), thus allowing you to reach tight spaces or hard-to-reach spots. Telescopic booms, by contrast, extend out in a straight line.

- Articulating boom lifts are ideal for reaching over or around places such as ceiling joists, roofs, warehouse shelves, etc.

- Telescopic boom lifts have more versatility to perform tasks that may be higher or farther out; they’re great for working at distances on worksites where operating close in isn’t an option. They’re good for things like building bridges and working high up on skyscrapers.

Vertical and Horizontal Reach

Another difference is their maximum reach capacity. Telescopic booms lifts typically have a higher vertical reach and horizontal reach than articulating booms. However, telescopic booms need a bigger workspace and plenty of room to achieve their extended reach.

- Articulating boom lifts have less reach than telescopic booms, but are more ideal for moving around certain obstacles or places.

- Telescopic boom lifts have a greater vertical reach and horizontal reach: up to 185 feet. They’re commonly used for highrise buildings.

Indoor vs. Outdoor Use

Are you working in an indoor warehouse or on rough outdoor terrain? Telescopic boom lifts would be the best choice for outdoor job sites with a lot of room and space to reach.

- Articulating boom lifts are ideal for indoor work since they can access narrow areas or walkways. They can be used for scanning in warehouses, which are often cluttered with stacks of inventory, and they can be used for maintenance work such as plumbing and ceiling repair.

- Telescopic boom lifts are commonly used in outdoor construction sites such as electrical work, painting, bridgework, or other tasks that require high or distant access.

Type of Engine

Your power source is an important factor to consider when choosing a boom lift. Indoor operations will likely call for an electric lift, while outdoor jobs may require more power from a diesel engine.

Diesel-Powered Engines

Diesel engines are generally used outdoors because of the fumes they emit. Both telescopic and articulating diesel lifts are available in larger models with a greater range of reach: telescopic lifts from 40 feet to 185 feet, and articulating lifts from 34 feet to 150 feet. Diesel engines emit fumes, but can also provide more power for dealing with rough terrain.

Electric-Powered Engines

Smaller articulating lifts, suitable for indoor use, are available to rent in 30- to 60-foot models (larger models are diesel-powered). These battery-powered engines don’t emit fumes and are quieter.

Boom Lift Attachments

Boom lifts can be equipped with various attachments, depending on the job you’re doing.

- Arrest bar: You can attach a lanyard to the horizontal track on this bar, allowing you to move freely and securely away from the platform (on a roof, for example).

- Tool tray: This can eliminate clutter and help operators organize tools on the lift, increasing efficiency and reducing the possibility that something might be dropped.

- Panel cradle: A panel cradle allows operators to place material outside of the platform; it can be used to lift things like plywood, drywall, and panes of glass.

- Pipe cradle: Panel cradles hold panels, and pipe cradles hold pipes for things like sprinkler systems; this attachment rests on the platform floor and is attached to the guardrails using U-bolts.

- Swing gate: This option allows for easy entry and exit when wearing a tool belt or carrying/loading materials.

Need to Rent a Boom Lift?

If you want to rent a boom lift, BigRentz offers an assortment of 20 articulating and telescopic boom lifts at daily, weekly, and monthly rates. Because these pieces of equipment are expensive to purchase, renting is your best option for most jobs.

Lifts from companies like Genie and JLG are available to rent or buy. A standard 30- to 40-foot boom lift can run you $25,000 to $75,000 new, or $20,000 to $40,000 used. Larger lifts can be $100,000 or even $200,000 new. By contrast, you can rent a 40-foot electric articulating lift for $243 a day or $1,401 a month. A 40-foot telescopic lift will run you $228 a day or $1,651 a month.

Need to rent an articulating boom lift or a telescopic boom lift? You can find 13 models of articulating lifts and seven models of telescopic lifts available from BigRentz.

Explore All Boom Lifts