Construction equipment management is assessing and managing construction equipment to ensure it meets project requirements and is used effectively and safely.

Construction equipment management is the process of monitoring construction equipment to ensure that it is used properly and safely and is well maintained. This includes evaluating fleet costs and usage, keeping machinery running and investing in the right equipment.

Table of Contents

- Why Good Construction Equipment Management Matters

- 9 Quick Tips for Better Construction Equipment Management

- How To Choose the Right Equipment

- Construction Equipment Maintenance and Inspections

- When To Retire and Replace Equipment

- Safety Considerations in Equipment Operations

- Construction Equipment Management Software

- Equipment Budgeting and Financial Management

Why Good Construction Equipment Management Matters

Construction equipment management considers factors such as cost, maintenance and usage. Good construction equipment management can help ensure a project is completed on time, safely and within budget. Proper equipment management can:

- Improve the longevity of equipment

- Decrease safety risks

- Reduce the potential for increased and unplanned costs

- Avoid projects running behind schedule and

- Reduce preventable injuries

The success of a project depends greatly on proper construction equipment management. Managers who take this seriously will be on top of which equipment gets the most and least use, when maintenance is due, what may need repairing or replacing and much more.

9 Quick Tips for Better Construction Equipment Management

There are many factors to consider when trying to better manage construction equipment. From maintenance to safety and storage, a construction manager ensures that workers properly take care of all equipment. Here are some top considerations for better construction equipment management.

- Create rules and guidelines: Construction managers should communicate with their team how to handle equipment properly and safely. Guidelines should be in writing and easily accessible to everyone. This information can help decrease wear and tear, reduce the amount of additional maintenance and repairs needed and improve safety. Use manufacturer guidelines to inform your own rules and guidelines, including things such as proper storage and maintenance schedules.

- Store your equipment properly: Proper storage is a big part of ensuring equipment lasts. Equipment should be shielded from elements when not in use to avoid rust and other damage. Initial budgeting should incorporate the additional costs of a storage facility costs or alternatives, like equipment covers.

- Keep on top of maintenance: Maintenance should be done regularly to prevent damage and keep equipment functioning well. Managers should assign someone to do regular inspections using guidelines about what to include in regular checks and signs of wear and tear. Manufacturer guidelines are also useful for maintenance as they will outline maintenance schedules. Another consideration is the condition of the work environment. For example, job sites with lots of dust or moisture may require more frequent equipment maintenance than what the manufacturer recommends.

- Create communication plans: A communication plan outlines the procedures for addressing issues and communicating that equipment is damaged or needs maintenance.

- Monitor equipment effectively: Monitoring equipment means keeping accurate logs of all pieces of equipment that you have, as well as logging who is using it and for what. There are applications that construction managers may use to help them monitor their equipment better.

- Keep equipment abilities and limitations in mind: Equipment should not be used beyond its capabilities or for tasks it’s not designed for. Misuse can lead to equipment damage, poor workmanship and potential injury.

- Implement security measures: Theft is a big concern on job sites. Security measures include keeping detailed records of all equipment with serial numbers and ensuring equipment is secured properly. You may also consider adding tracking to equipment or hiring private security for larger sites.

- Monitor equipment utilization: It’s important to monitor how often workers use equipment. Overuse will impact wear and tear and have potential budget implications for increased maintenance or replacement. Alternatively, underuse may be an opportunity to sell the equipment or replace it with rental equipment.

- Ensure everyone has proper training: Workers need to know how to use equipment properly and safely. Use a combination of training methods, such as classroom style, readings, hands-on demonstrations and 1-on-1 training with more experienced operators.

How To Choose the Right Equipment

Another critical aspect of construction equipment management is choosing the right equipment for different projects. Each project and job site will have different specifications that require different equipment types. Here are some of the ways that you can choose the right construction equipment for your project.

- Assess Project Needs: First, you should consider the requirements of the projects and what equipment will best finish the project on time and within budget. Each project will have different needs, but looking at similar past projects is a good starting point.

- Evaluate Site Conditions: The site location and conditions will be important in choosing equipment. The terrain, the climate, the amount of space, etc., will influence equipment needs.

- Determine Your Budget: Budget will be one of the biggest determining factors of what equipment to use. Depending on the project’s equipment budget, your choices for equipment may be limited.

- Research Suppliers: Look for reputable suppliers in your area that can provide the equipment you need for the dates that you need it.

- Final Selection: Before selecting equipment, you’ll need to review the warranties and sign the contract.

Construction Equipment Maintenance and Inspections

Maintaining equipment is one of the most critical pieces of construction equipment management. From ensuring that you get the most usage out of your equipment to enhancing safety and reducing potential downtime, equipment maintenance should be a priority. Completing regular inspections is a great preventive measure to ensure that any issues are addressed before they cause delays or even injuries. Depending on your region, you will have to follow specific health and safety protocols for maintenance and inspections. Always follow the guidelines of the local health and safety authority.

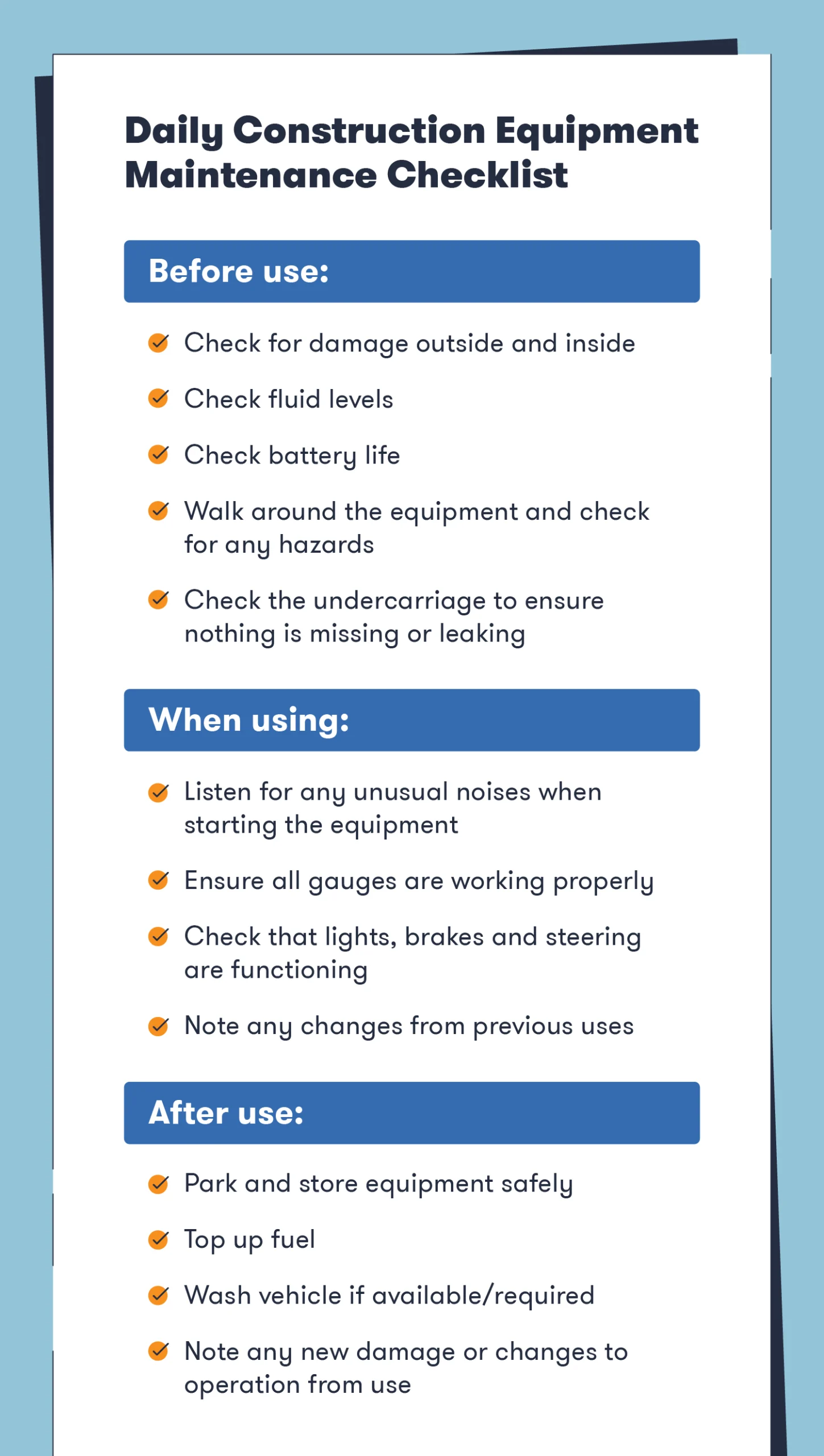

Daily Construction Equipment Maintenance Checklist:

Before use:

- Check for damage outside and inside

- Check fluid levels

- Check battery life

- Walk around the equipment and check for any hazards

- Check the undercarriage to ensure nothing is missing or leaking

When using:

- Listen for any unusual noises when starting the equipment

- Ensure all gauges are working properly

- Check that lights, brakes and steering are functioning

- Note any changes from previous uses

At the end of use:

- Park and store equipment safely

- Top up fuel

- Wash vehicle if available/required

- Note any new damage or changes to operation from use

When To Retire and Replace Equipment

As much as maintenance is critical, it’s also important to know when maintenance isn’t worth it anymore. Many factors may contribute to deciding to replace or get rid of a piece of equipment. Here are some things to consider:

- Age and Usage: Manufacturer guidelines will indicate how long equipment lasts with typical use. However, you will have to identify your usage and whether it’s above or below the typical threshold.

- Repair Costs: If a machine is costing more in repairs than the usage you’re getting out of it, it’s likely time to retire it. Additionally, if you’re spending a lot of money maintaining a piece of equipment that needs replacing soon, it may be time just to replace it now.

- Technological Advances: Some machinery may continue to operate well but still be considered out-of-date. If a new piece of equipment can do the job better and more efficiently, it may be time to replace the old one.

- Project Needs: The needs of a construction project are constantly changing. A piece of equipment that was crucial at the start of a project may be unnecessary later on. An integral part of construction equipment management is assessing the project’s needs continually and adjusting appropriately, including selling or returning equipment you no longer need.

- Safety Compliance: As equipment gets older and outdated, there may be safety issues. If the equipment doesn’t meet the latest safety or environmental standards, it’s time to get rid of it.

Explore Equipment Rentals

Safety Considerations in Equipment Operations

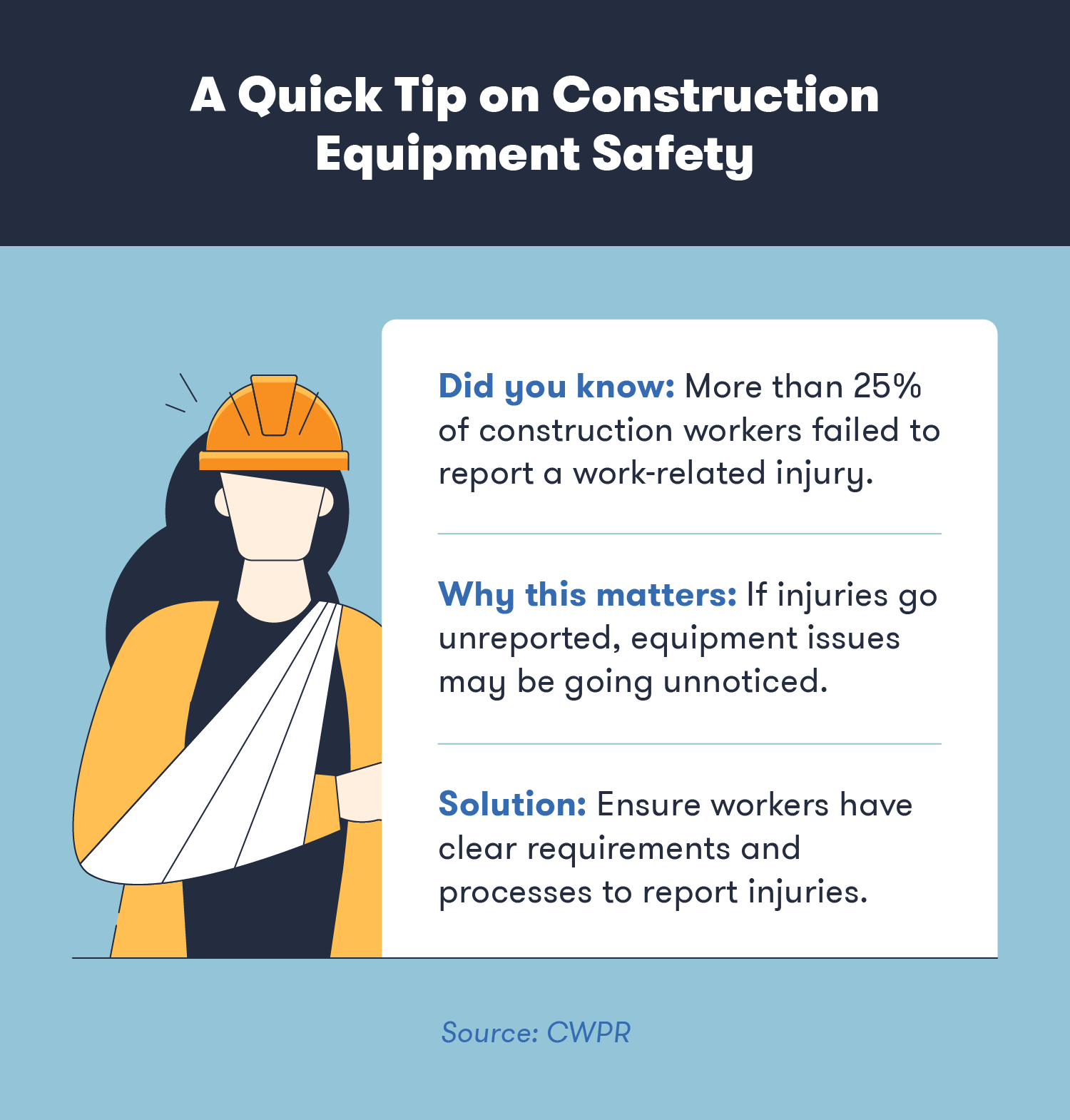

Safety is one of, if not the most, important parts of construction equipment management. Ensuring that equipment is safe and workers know how to safely operate equipment is critical. Unsafe job sites can not only lead to injuries but are also a risk to keeping on schedule and budget. Since managers can’t be everywhere at once, it’s important to have a team of properly trained operators. Well-trained operators are not only important for safety but can also help with keeping up on maintenance. All operators should be trained on how to use equipment properly and safely. In addition to proper training, construction managers should create operation and safety guidelines that are available to all employees. This should include things like proper equipment handling, safety rules and procedures and information on first aid and what to do in an emergency.

Construction Equipment Management Software

Construction managers can use many different types of software to help manage and track their equipment. The advantage of using software is that it helps to centralize information into one source of truth. Operators will generally be able to enter information about equipment, whether that means recording issues or requests for repair or just tracking regular maintenance. Here is some of the software that can be useful for construction equipment management.

Autodesk Build

Autodesk’s construction management software features project, quality and safety management, as well as cost control tools. Autodesk Build includes mobile punch lists, customized reports, predictive insights and standardized forms, as well as their project scheduling software.

Workyard

Workyard is designed specifically for construction scheduling. The software offers a variety of features, with a focus on labor and work order management. Workyard includes job scheduling, geofencing, a GPS time clock app, the ability to track and add notes to tasks and equipment tracking, among many other features.

TruckIT

TruckIT is a productivity tool to help those who manage heavy trucks and equipment. The application programming (API)-based software is good for organizations that want to use multiple software for their construction equipment management. The software helps with fleet management, optimizing dispatching, reporting and analytics and back office automation.

SiteSense

SiteSense by Intelliwave Technologies is a materials management construction software. SiteSense has several different products, is used globally and integrates with several other software. They brand themselves as the “construction software fit for everyone.”

Milwaukee ONE-KEY™

ONE-KEY™ is a tool and equipment tracking software. Bluetooth tags are added to equipment to track, and then the cloud-based software allows data input to keep track of the location, usage and maintenance of a piece of equipment.

Equipment Budgeting and Financial Management

Another one of the big responsibilities of a construction manager is budgeting. While managers may not set the budget, they are often responsible for determining how to implement it effectively. There are many costs to consider, from start-up equipment costs to labor and even planning for unexpected costs such as maintenance or unplanned downtime, that a manager will have to consider.

Here are a few of the construction equipment management costs that managers need to keep in mind.

Acquisition Costs

Much of the initial costs of a construction project will be in acquisition costs, which, when referring to equipment, are the costs of purchasing or renting the equipment needed. At this stage, research is extremely valuable. Costs of different vendors should be compared, as well as considering whether it’s worth it to buy new equipment or rent.

Operating Costs

Another high cost for construction equipment management is operating costs. This includes fuel, regular maintenance and any unscheduled repairs. While this cost can be partially predicted, most projects will face incidental expenses, which should be accounted for in initial budgeting.

Depreciation

Construction equipment depreciation is calculated in several ways. One is useful life depreciation, which is the general anticipated time a piece of equipment is expected to operate. Another is straight-line depreciation, which divides the cost of the equipment by its useful life value. This should give a percentage value that the equipment is depreciating each year. Because the value of construction equipment depreciates, it may be better to rent equipment, particularly if it’s only needed for a specific project.

Storage Costs

Another budget factor to consider is the cost of storage. As previously mentioned, storage cost will depend on the equipment itself, the space required and the level of security needed.

Insurance

Heavy equipment insurance will protect your equipment in instances of damage, needed repairs and theft. There are many different options for insurance, with varying degrees of coverage. It’s a good idea to shop around and compare rates to get the best coverage for the best price. Construction equipment management requires much planning but is made simple by breaking it down into different functions such as maintenance, safety and budgeting. Looking for equipment rentals? BigRentz offers a wide variety of equipment at an affordable price. Take a look at the many construction equipment rentals available from BigRentz.