If you’ve ever considered a career in the construction industry, you may wonder what it takes to become a heavy equipment operator (HEO). Whether driving a bulldozer, operating tower cranes, or running a backhoe, HEOs perform essential work on a variety of equipment for any construction project. As a construction equipment operator, you may participate in a wide range of tasks from installing foundations and digging pools to transporting heavy materials and working on important infrastructure projects.

If you want to become a heavy equipment operator, this article discusses the steps to take and skills required to operate heavy equipment and salary ranges based on equipment type.

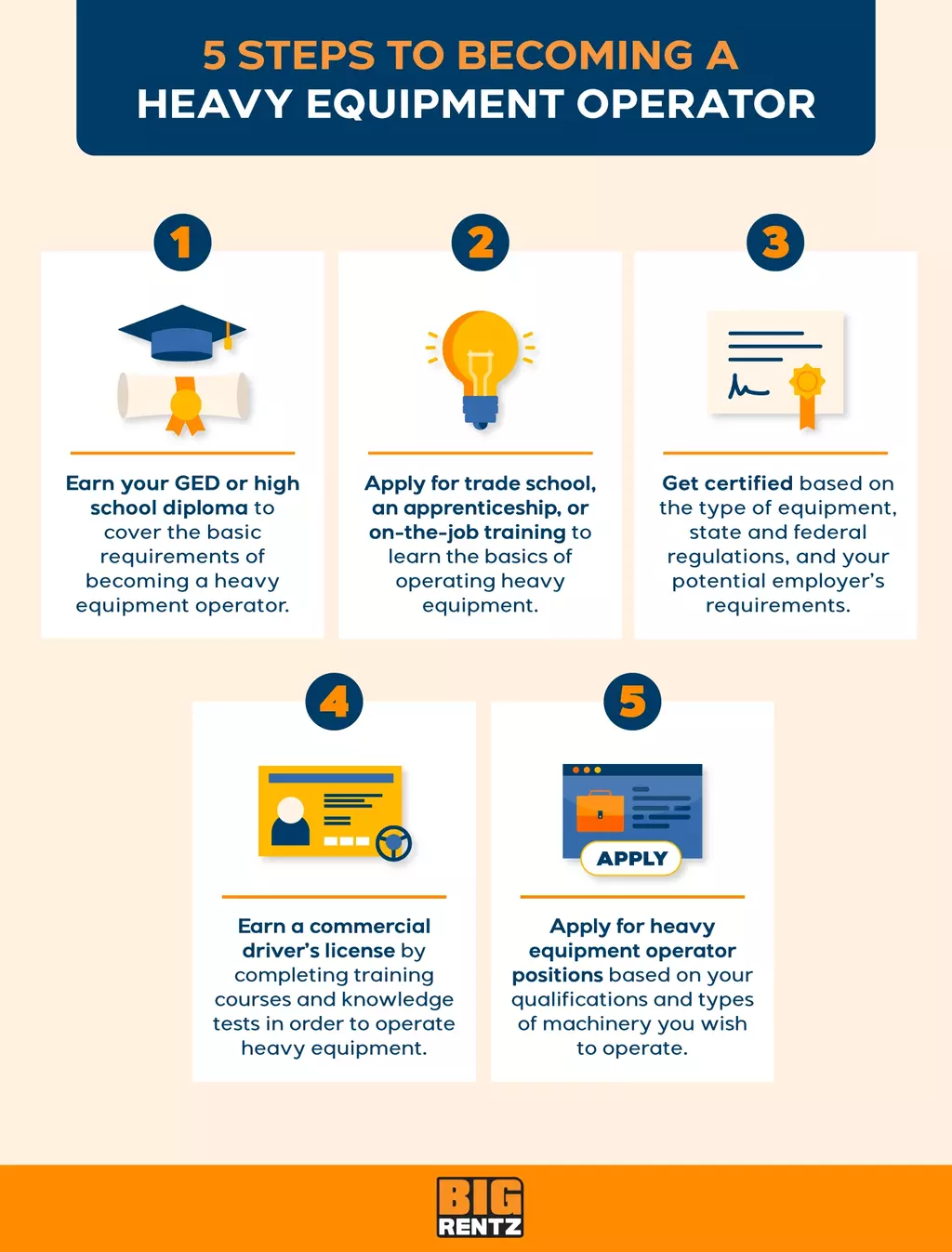

How to Become a Heavy Equipment Operator

Heavy equipment operator requirements generally include a combination of education and practical experience, usually consisting of a high school diploma or GED followed by vocational training — at a trade school, an apprenticeship, or relevant on-the-job training. You may also need certifications and licenses as required by law, but this depends on the equipment type as well as your state’s laws.

1. Earn your GED or high school diploma

Construction equipment operators typically need to have a high school diploma or a GED. Classes in math and automotive mechanics may prove particularly useful, as HEOs may maintain and repair their own equipment.

2. Apply for trade school, an apprenticeship, or on-the-job training

After completing your high school education or equivalent, you can focus on the practical component of your training. Here are a few options:

School

Vocational schools offer classes to learn how to operate heavy equipment. While some schools use advanced simulators in their training programs, you should make sure that your course of study also includes real-world experience if you choose this route.

You may learn heavy equipment operation as part of a two-year degree at a community college or a shorter certificate program at a technical school, but remember that these training schools cost money and may not give you as much hands-on experience as apprenticeships and on-the-job training.

Apprenticeship

Work-based learning programs typically lasting three to four years, apprenticeships combine structured technical instruction with paid on-the-job experience. Apprenticeships are one of the more common methods for becoming a heavy equipment operator. The educational part of the program teaches you operating procedures, safety practices, first aid, and how to read grading plans. During field training, you will learn how to operate machinery, maintain equipment, and use technology like GPS devices.

On-the-job training

To get started directly on your career in construction, you may look into job opportunities as a laborer at a local excavating or landscaping company. While you likely won’t begin operating heavy machinery right away without experience, as an entry-level laborer you can ask your future employer whether they offer on-the-job training so that you can grow your skills.

3. Get certified

The Occupational Safety and Health Administration (OSHA) doesn’t provide a certification for heavy equipment operators, but it does require employers to train and instruct employees on safe equipment operation. In addition, some states and cities require special licenses for the operators of specific machines like backhoes, loaders, cranes, pile drivers, and bulldozers.

Contact your state or local licensing board for more information or look for heavy equipment operator schools in your area. Many unions run these schools and offer apprenticeship training. Even if your location doesn’t have specific requirements, a certificate program can help you understand the equipment better and operate it more safely.

4. Earn a commercial driver’s license

Some states require a commercial driver’s license (CDL) for certain tasks, such as driving dump trucks and other construction vehicles over a certain weight on roads. Getting a CDL involves the following steps:

- Determine which class of CDL you need based on the type of equipment you want to operate.

- Class A: The greater of multiple vehicles with gross weights exceeding more than 26,001 pounds, including towed gross weights exceeding 10,000 pounds.

- Class B: A single vehicle with gross weight exceeding more than 26,001 pounds, or a single vehicle’s gross weight of 10,000 pounds or less.

- Class C: A single vehicle used to transport 16+ passengers, or hazardous materials.

- Complete the Federal Motor Carrier Safety Administration (FMCSA) driver training courses.

- Pass a Department of Transportation (DOT) medical exam, driving record check, and skills and written tests.

- Receive a commercial learner’s permit (CLP) after passing all tests.

- Pass all three parts of the Skills Test — Vehicle Inspection Test, Basic Controls Test, and Road Test — after having your CLP for 14 days.

5. Apply for heavy equipment operator positions

After completing your education and training, you’re ready to start applying for heavy equipment operator jobs (if you haven’t already secured a permanent position through your apprenticeship program, that is). Make sure to update your resume with all the new training, skills, knowledge, and certifications you gained while preparing for your new position.

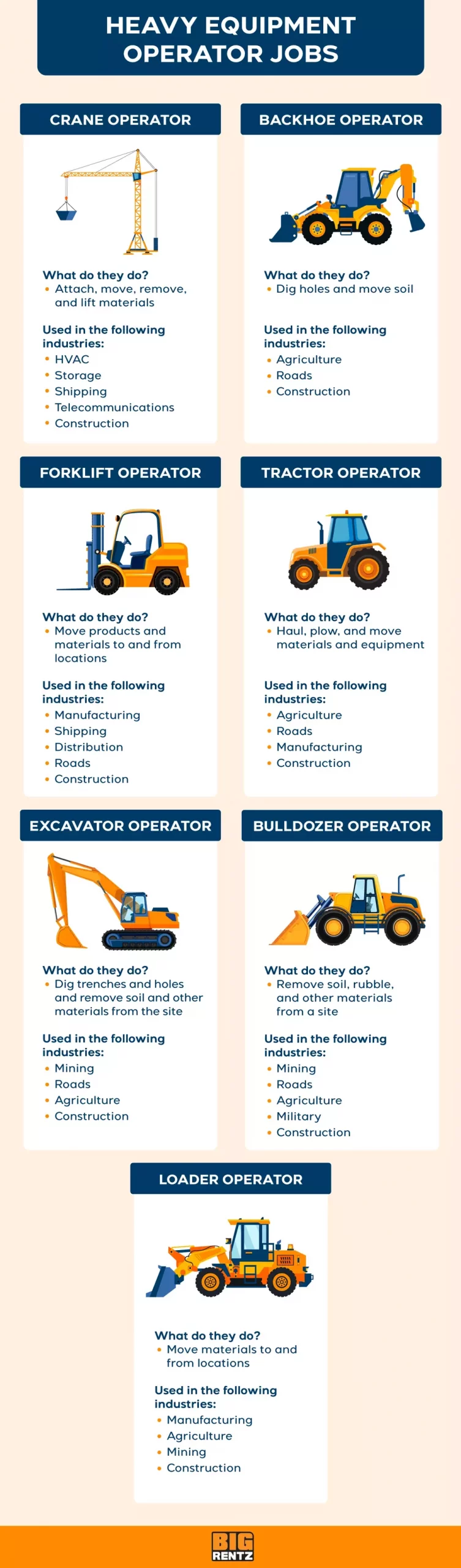

Popular types of heavy equipment

The following types of heavy construction equipment need skilled machine operators to run them:

- Crane: Cranes perform tasks like moving building materials on construction sites, hoisting loads off trucks and cargo ships, and operating industrial workstations. In addition to controlling the activities of specialized cranes on the job site, crane operators generally must calculate load capacity, inspect clearances and obstructions, maintain equipment in proper working order, and record operating activities.

- Backhoe: A popular type of construction vehicle, the backhoe performs a variety of excavation and digging tasks in construction, landscaping, and agriculture. As a backhoe operator, you will use the machine to shovel through material to dig holes, excavate soil, break up surfaces, and transport materials. You must also maintain safe operation procedures and compliance with safety policies, including inspecting and maintaining your equipment.

- Forklift: Forklifts excel at lifting, lowering, and transporting materials short distances, such as pallet stacking in a warehouse or unloading trucks at a construction site. As a forklift operator, you will stack and unstack materials and goods, move loads from one location to another, safely maneuver the vehicle in busy environments, and regularly inspect your equipment and site for safety concerns. Because forklift operation requires special training and skills—such as foot coordination and good hand-eye coordination—you may need to look into getting a forklift certification.

- Tractor: Indispensable on farms, tractors can also help with a variety of construction and landscaping projects. As a tractor operator, you will control the vehicle and use attachments as needed to perform a variety of tasks such as transporting, hauling, plowing, harvesting, and moving materials around a site. Your employer may also ask you to perform routine maintenance and keep records of all equipment repairs.

- Excavator: Excavators perform tasks like landscape grading, pool digging, hole drilling, and canal dredging. Excavator operators must safely operate machinery for multiple uses (such as excavation and demolition), follow safety standards, and inspect and maintain equipment.

- Bulldozer: These heavy-duty earthmoving machines excel at pushing, excavating, and leveling tasks. Bulldozer operators control the unit to remove or move sand, soil, gravel, and other loose matter from one place to another, grade terrain, and more. They may also need to clean, maintain, and repair their equipment.

- Loader: Loaders help agricultural, landscaping, and construction workers transport heavy materials across a work site. Besides using the loader to load and unload materials, operators may need to control additional attachments, inspect equipment and make necessary repairs, and monitor the machine and site for potential hazards.

How much does a heavy equipment operator make?

Construction equipment operators receive a median pay of $48,290 per year or $23.22 per hour, according to 2021 U.S. Bureau of Labor Statistics numbers. With an estimated increase of 24,900 jobs (or 5%) between 2020 and 2030, this profession has a lower than average job outlook.

| Types of Heavy Equipment Operators | 2021 Median Hourly Pay | 2021 Median Annual Pay |

| Crane and tower | $29.92 | $62,240 |

| Backhoe, bulldozer, excavator, and loader | $23.22 | $48,290 |

| Forklift, truck, and tractor | $18.45 | $38,380 |

What skills do heavy equipment operators need?

While the specific skills required may vary by the specific machine or job, most heavy equipment operators need the following abilities:

- Depth perception: When you operate equipment that pushes, reaches for, picks up, and/or places all sorts of goods and materials, good depth perception is a must.

- Agility and coordination: Your hands and feet perform separate movements when operating heavy equipment. You need quick reaction time coupled with coordination to make different movements with each hand and foot while moving the equipment.

- Physical strength (enough to lift 50 pounds): While the machine does most of the heavy lifting, you may also need to pick up or push containers, instruments, or materials by hand.

- Mechanical knowledge: HEO jobs may require you to troubleshoot mechanical problems and perform minor mechanical repairs on your equipment.

- Verbal and written communication: Heavy equipment operators must be able to understand written materials, follow instructions, communicate with supervisors and co-workers, and keep a log of activities and repairs.

If you have physical strength, the stamina to work in challenging conditions, and solid mechanical skills — or interest in obtaining them — then a career path in heavy equipment operation might be for you. With a high school diploma or GED, you can receive heavy equipment operator training on the job, through an apprenticeship, or at vocational schools. Adding a machine-specific certification may help you take your career to the next level.