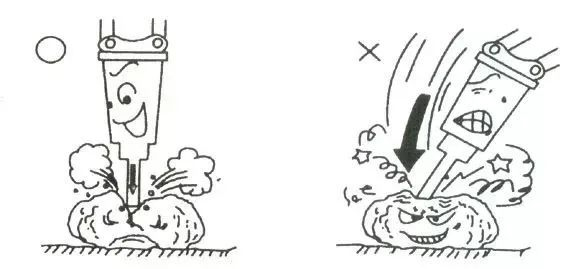

As we all know, the installation and use of some external devices can endow the excavator with different uses and improve the work efficiency in specific scenarios. Among them, the use of the excavator breaker is believed to be familiar to many operators. However, the neglect of some details and non-standard operation during use will have adverse effects on our devices and machines.

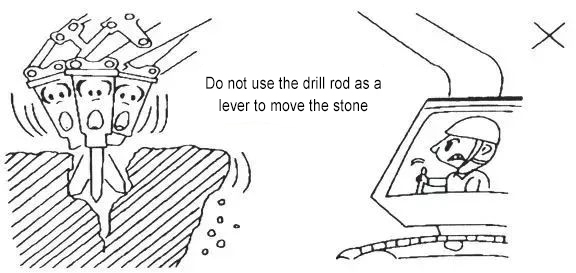

Adjust the position of the steel brazing

In order to better exert the impact force of the excavator breaker, the steel drill must be prevented from being in a suitable position. If the position is not suitable, the impact force of the piston will be weakened and the stone cannot be sufficiently broken. This will cause the body of the excavator breaker and the large and small arms of the excavator to be greatly impacted, resulting in damage to these parts.

On the contrary, if the working position is too far or too close, when the rock is broken, the excavator will suddenly tilt forward, and the lower end of the breaker main body or the shell will collide violently with the rock, causing damage.

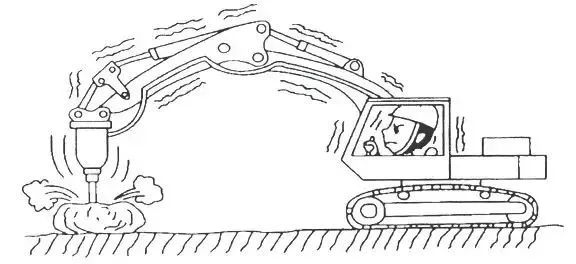

During the impact operation, the vibration is transmitted through the equipment host, and the position of the breaker should be adjusted frequently, and special attention should be paid to the prohibition of impact operation under abnormal conditions.

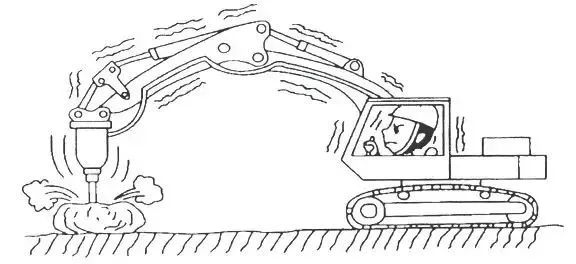

Steel brazing direction

The direction of the steel drill and the forearm should be the same, and the steel drill and the rock surface should be as vertical as possible. If the steel drill and the rock surface are not vertical, the steel drill may slip during the operation. When crushing, firstly adjust the steel drill completely, and under stable conditions, select the hitting point of the rock to perform the impact operation.

The correct use method can improve the life and work efficiency of the excavator breaker.